- +90 (537) 952 14 81

- info@itppack.com

- İstanbul, Türkiye

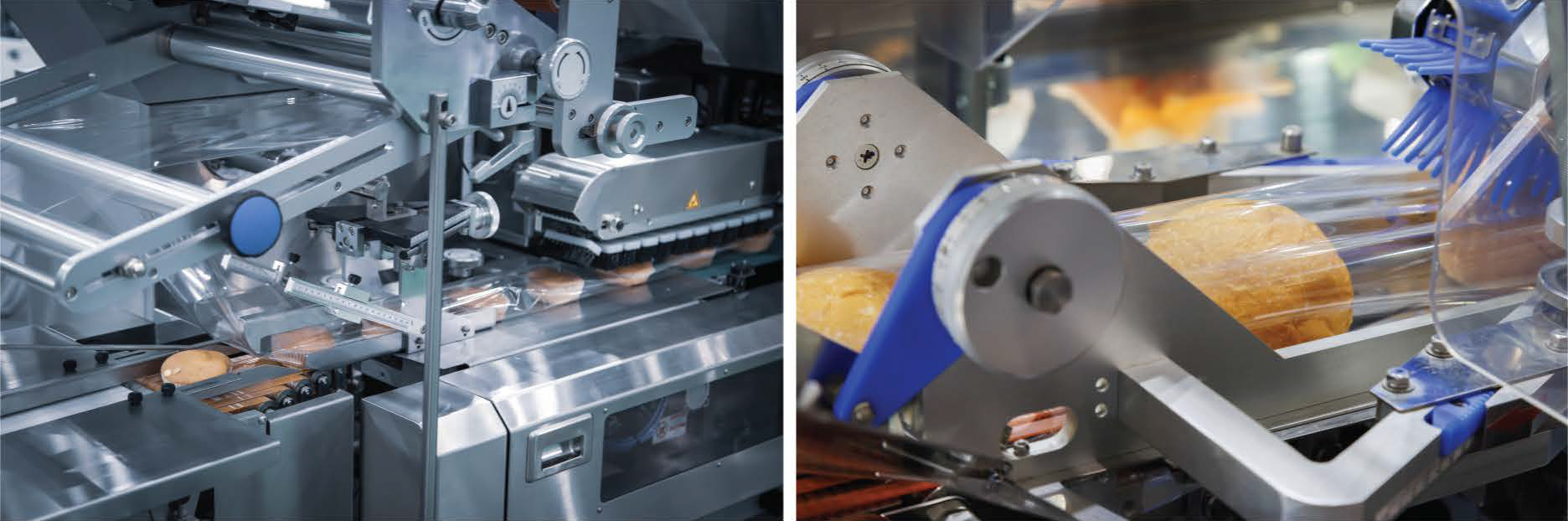

Flowpack Packaging

Flowpack Packaging

Flowpack packaging is an innovative method widely preferred by various industrial sectors today. It is commonly used in the food, pharmaceutical, cleaning products, electronics, and personal care industries. This system offers significant advantages in terms of speed, efficiency, and aesthetics. Flowpack packaging is an automatic system that ensures products are packaged quickly and with high quality in mass production.

What is Flowpack Packaging?

Flowpack packaging is a system where products are tightly and uniformly packaged in pouches or containers. This method typically uses transparent film material to package products individually or in groups. Flowpack machines are automatic systems that feed film rolls, wrap the product, seal the edges with heat, and package the product neatly. The product is fed into the machine via a conveyor belt, and the process is completed step by step. After the packaging process, the products are ready with transparent or printed pouches that display product information and the brand logo.

Advantages of Flowpack Packaging

High Speed and Efficiency: Flowpack packaging machines operate at very high speeds due to their automated systems. This accelerates the production process and provides a significant advantage in large-volume production. Machines that operate smoothly and continuously maximize production capacity.

Visual Appeal and Easy Labeling: Flowpack packaging uses transparent plastic films or specially printed films, making products visually more appealing on shelves or in stores. Additionally, brand logos, product information, and instructions can be printed directly onto the packaging, offering significant marketing opportunities.

Product Safety and Protection: Flowpack packaging helps protect products from external factors such as air, moisture, light, and dust. This is especially crucial for preserving the quality of food and healthcare products.

Versatility for Various Product Types: Flowpack packaging is suitable for a wide range of products. From food to personal care items, electronic components to pharmaceuticals, many different types of products can be easily packaged using this system. Customizable systems cater to products of different sizes.

Environmentally Friendly and Sustainability: Flowpack packaging systems can utilize eco-friendly materials. Recyclable film materials make this packaging sustainable. For environmentally conscious brands, this feature is of great importance. At ITP Pack, we aim to provide nature-friendly products with sustainable solutions.

Low-Cost Packaging Solution: Flowpack packaging offers a cost-effective solution due to its automatic machines, which reduce labor costs and increase production speed. Additionally, the system allows for quick and easy changes to pouches and packaging, making it an economically efficient solution for businesses.

Flowpack Packaging Process

The Flowpack packaging process consists of several main steps:

Preparing the Film Material: First, the film material used for packaging is fed into the machine. This film is typically made of plastic or biodegradable materials, and if printing is required, logos and other visuals are added at this stage.

Preparing the Products: The products to be packaged are conveyed to the Flowpack machine via a conveyor system. The products are arranged in a specific order to ensure that each item is packaged uniformly.

Packaging and Sealing: The product is wrapped with the film, and both ends are sealed with heat. This process ensures the packaging is hermetic, meaning the contents are completely protected from external factors. The film material tightly wraps around the product.

Cutting and Exiting the Packages: The packaged products are cut from the machine and exit in an orderly manner. These packages are gathered in production lines or storage areas.

Final Inspection and Packaging: Finally, the packages are inspected for any defects. If any packaging is faulty, it is separated and reprocessed.

ITP Pack and Flowpack Packaging Solutions

At ITP Pack, we specialize in Flowpack packaging systems and provide customized solutions tailored to our customers’ needs. With our state-of-the-art machines and high-quality materials, we ensure the safety and visual appeal of your products. We also contribute to your sustainability goals with eco-friendly packaging solutions.

Flowpack packaging plays a vital role in today’s fast, efficient, and aesthetically focused production world. We at ITP Pack would be happy to collaborate with you to package your products in the best way possible and add value to your brand.

- nostrum exercitationem ullam

- Quis autem vel eum iure

- vel illum qui dolorem eum

- nostrum exercitationem ullam

- Quis autem vel eum iure

- vel illum qui dolorem eum

Expert Team

Modern Technology

We provide fast and reliable solutions with our automation systems.

Flexibility

Your Value Partner

Innovative Solutions

Secure Packaging

Corporate

About Us

© 2024 ITP PACK • All Rights Reserved.